Engineering Surveys

MJ Rees has been supporting engineering projects of all sizes for over four decades. Our promise is to provide clients with the highest level of accuracy using the latest in engineering survey equipment and total stations.

Our surveyors have a wealth of experience working with design drawings and are fully trained in the latest health and safety procedures. They also hold current CSCS cards and Network Rail’s Personal Track Safety (PTS) certifications.

On site, our teams use Trimble robotic total stations and GPS technology to provide comprehensive, rapid and accurate reports. We also have a thorough in-house quality checking system to ensure the highest standards of reporting every time. Reports are provided alongside CAD drawings in DXF/DWG or DGN formats. We’ve provided engineering surveys for rail, road and bridge projects; road and highway improvements; reservoir and dam monitoring; sewage treatment works and pipeline route; and coastal flood prevention schemes.

Earthworks and volumetric calculations

When reconfiguring the topography of a site to achieve design levels, earthworks and volumetric calculations are essential.

We use the latest technology to collect and provide clients with accurate data in the form of 3D CAD models, sections, profile drawings and spreadsheet reports. Our data highlights areas of cut and fill to give you a better interpretation of the project.

We provide earthworks and volumetric surveys for a range of projects including Cemex plants and Thames Water sites.

Setting out

Our experienced engineering surveyors use Trimble survey instruments, engineers’ design drawings and design coordinates to accurately set out required points on a variety of sites.

Collaboration is key and we work closely with clients to provide a flexible and reliable service – with ongoing phases of works always in mind.

Frequently Asked Questions

What is an engineering survey?

An engineering survey is a high accuracy survey used to gather detailed data and measurements to RICS survey detail accuracy band D (+/-10m) to band A (+/-2mm). Clients will specify this level of accuracy when designing and fabricating replacement elements of a structure.

What considerations might need to be made when conducting an engineering survey that don’t always apply to routine topographical survey?

When working to these tolerances surveyors need to consider all the factors that contribute to the error budget. For standard topographical surveys the accuracy required is relatively easy to achieve, however factors such as corrections (temperature and pressure), instrument type and specification (angular and distance accuracy of a total station or laser scanner positional accuracy), centering errors and registration errors all need to be considered when designing a survey. Qualified and experienced surveyors should be employed to make these decisions.

How do you assess the accuracy of the survey?

Once the contributing factors are understood then statistic formulae can be applied to calculate the net effect of the contributing errors and the mitigation employed (for example multiple rounds of angles and distances). Anticipated accuracies can be checked by independent measurement employing a different methodology.

What equipment might be used in engineering survey?

Equipment likely to be used will be familiar to all surveyors. However, the specification of the devices won’t necessarily be that in use every day:

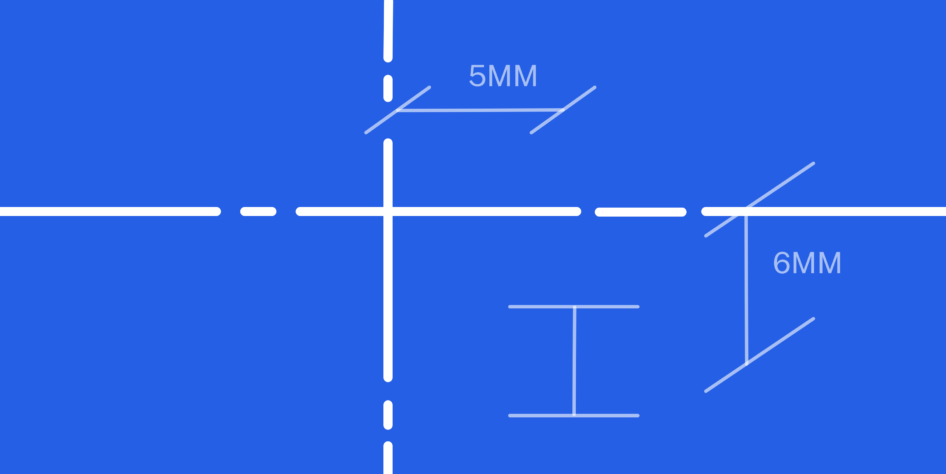

High end total stations Usually measuring angles to 1 second or better and distances to 1mm or less.

Laser Scanner Terrestrial laser scanners specification would need to be considered. Registration with targets is essential rather than relying on scan to scan.

Higher specification digital Level Capable of measuring to 1mm or less using standard or an invar staff.

GPS/GNSS Not normally used for high relative accuracy work but does provide absolute geo location.