Structural Monitoring

We tailor monitoring to your specific structure or project – either integrating an existing scheme or setting up a new one. Monitoring can take place across all time periods from annual settlement monitoring to hourly monitoring of structural steel during works. Our structural monitoring services are undertaken by a team of experienced land surveyors.

Precision is key when it comes to monitoring structural movement. Our monitoring is performed to the highest accuracy using sub-millimetre digital levels and one-second accuracy total stations to allow as much redundancy as possible.

Frequently Asked Questions

What are the relevant questions before planning a structural monitoring scheme?

In order to design a successful scheme, there are questions to consider first:

- Type of deliverables that are required This might range from a excel spreadsheet with levels to a web portal reporting continuously with alarms at predetermined thresholds.

- Accuracy/Tolerance A realistic level of accuracy needs to be defined so the right equipment can be selected for the job to meet the specification. Asking for too high an accuracy introduces unnecessary expense.

- Frequency of data How often does the data need to be collected? Monitoring can be continuous, weekly, monthly or annually.

- Size and type of movement or potential failure to be expected This can help to define where the monitoring points are to be installed and what type of monitoring equipment is best suited.

- Length of monitoring Longer periods of monitoring require more permanent targets and justify the use of more sophisticated technology. For longer periods the higher costs can be spread over months or years of the project.

What form can structural monitoring take?

Structural monitoring can take several forms from simple checks with crack gauges to permanent installations with total stations, electronic tilt meters and crack gauges measuring a structure at critical points.

- Crack gauges record the progress of cracks in structures by recording 2-dimensional displacement. They might be used on their own or combined with other technology.

- Precise levelling is used to monitor changes in elevation to an accuracy of a few millimetres or even sub millimetre.

- Total Stations are used to monitor 3-dimensional displacement and can typically achieve 1-5mm.

- Tilt metres provide sub millimetre results usually combined with a beam to sense movement over a 1-2m section of wall.

- Electronic crack gauges

Can structural monitoring provide the causes of movement?

Structural monitoring cannot provide the exact cause of movement, but it can provide information on how and when the structure is moving, which can be used to infer what might be the cause of the movement.

How can the results of structural monitoring be presented?

The final report can take several forms depending on the budget and sophistication of the project.

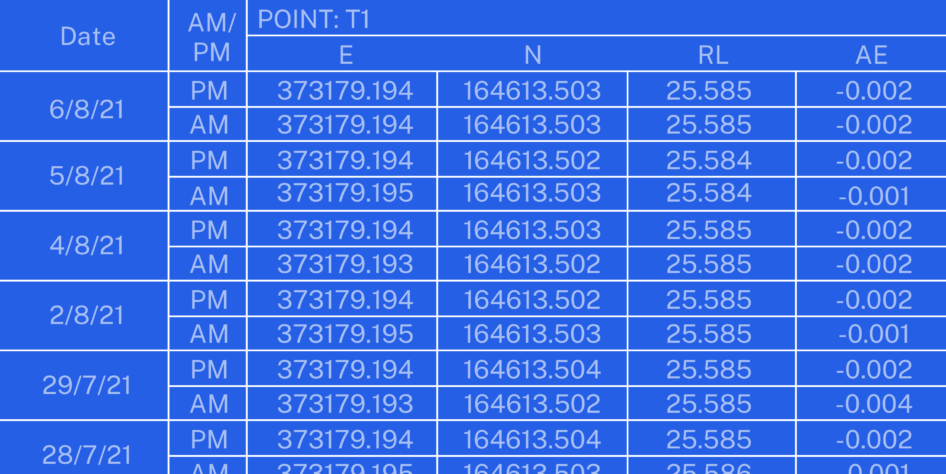

Excel spreadsheet showing the level or 3d co-ordinates compared to the original datum values. Movement can be graphed to help identify trends.

Photographs might be included to help with interpretation.

Drawings might be included perhaps as a profile to show how a section changes over time or as “heatmaps” of a wall to show the areas exhibiting the most movement.

Instead of documents the data can be presented to the client via an on-line portal such as Trimble 4d. Automatic alarms can be set up that inform the client via SMS and email when preset thresholds have been breached. This enables them to react to changes before any potential problem. Data from other sensors such as weather stations (outputting wind speed, temperature, pressure) can be displayed with the movement monitoring.